|

|

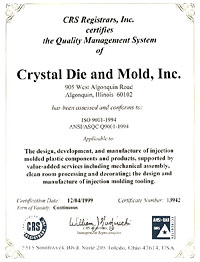

ISO Registration and CDM: Our Story

There are a number of reasons why a company chooses to adopt the quality system requirements that ISO 9001 possesses, but ours was simple - we chose this quality system because it would help us reach our established management objectives and provide a vehicle for continual improvement. An equally important by-product of our effort was that the quality system guidelines would enable us to be a more proactive supplier for our customers. The day the news was announced that the Registering Board approved our Auditor's recommendations for ISO 9001 registration was extraordinary for everyone at Crystal Die and Mold. It was another great milestone as a world class full service plastic supplier. Our senior executive management had the foresight to see that what we were building was going to dramatically improve our way of doing business - and they used that to help motivate and encourage our team throughout the entire implementation process. After our successful registration audit we have been able to maintain this level of success by performing not only the required internal quality audits with our formally trained internal auditors but also our own employee-created validation process to fill the gap between subsequent audits. Our validation process, without question, assisted in our goal of not only maintaining but also exceeding expectations. Our future plans at Crystal Die and Mold are for the smooth transition from the ISO9001: 1994 standard to the new ISO9001: 2000 revision. Our transition focuses primarily on management responsibility, documentation, training and continuous improvement. We are very excited about the new standard and look forward to the challenges ahead of us. New Technology at Crystal Die and Mold, Inc.

Heat transfer combines both pad printing and hot stamping methods without the challenges of messy ink. The label itself is screen printed on the carrier at the label manufacturer. CDM procures the finished fully cured labels and threads them onto a hot stamping press with a heat transfer feeder. A single hit can produce multiple colors with this dry process. Very tight tolerances can be held with heat transfer using our state-of-the-art equipment. Obvious benefits include:

GLOBAL PARTNERING WITH CDM

We have successfully partnered with other U.S. molders and have developed a process by which we manage the business and quality aspects of our programs but utilize the molding capacity of our alliances. Logistically successful, we are closer to our customer's manufacturing facilities and continue to exceed their expectations on quality and delivery. Contact our Sales Department if your company is interested in participating in CDM's Global Partnering Program.

Crystal

Die & Mold, Inc. Copyright © 2001, Crystal Die & Mold, Inc. All rights reserved. |

A

question was posed to our management team one day by senior

executive management. They inquired, how could we better serve

our customers and provide them with the ongoing quality and

continuous improvement that is the driving force of today and

tomorrow's business world? After thoughtful consideration of

all alternatives, the ISO 9001 format was suggested.

A

question was posed to our management team one day by senior

executive management. They inquired, how could we better serve

our customers and provide them with the ongoing quality and

continuous improvement that is the driving force of today and

tomorrow's business world? After thoughtful consideration of

all alternatives, the ISO 9001 format was suggested.

HEAT

TRANSFER is one of the latest techniques introduced in CDM 's

Secondary Operations. The process was introduced a few years

ago but has greatly advanced each year and is quickly becoming

the decorating technique of choice by many of our customers.

HEAT

TRANSFER is one of the latest techniques introduced in CDM 's

Secondary Operations. The process was introduced a few years

ago but has greatly advanced each year and is quickly becoming

the decorating technique of choice by many of our customers. In

an effort to expand CDM's global presence for our customer base,

we are developing partnerships with a number of molders in the

Far East, Asia and Europe. Our Sales and Marketing efforts have

taken us to potential joint ventures in Japan, China, Singapore

and Europe.

In

an effort to expand CDM's global presence for our customer base,

we are developing partnerships with a number of molders in the

Far East, Asia and Europe. Our Sales and Marketing efforts have

taken us to potential joint ventures in Japan, China, Singapore

and Europe.